Custom Plastic Packaging Design Capabilities

At Agreen Clear Packaging, the ability to customize plastic packaging is endless! Our transparent product packaging includes optional style features. We can customize silk screen printing, embossing, custom plastic die cutting, flexible thread service, foil printing and stamping, fragrance packaging, sustainable packaging, rigid window pick and place, and die-cutting for you. Packaging windows and inserts. We provide creative structural packaging designs for multiple product markets. Discover a variety of plastic packaging designs in Agreen Clear Packaging, from health and beauty products, food and beverage products, wine and spirits products, pharmaceutical products, mobile phone products, stationery products, promotional and club packaging products, home entertainment products, clothing products, etc. Package!

Custom Silk Screen clear plastic box packaging

With the look of clear plastic, PVC, or acetate, clear PET is strong, recyclable, and perfect for upscale packaging that requires silk screen printing.

CMYK Color Offset printing clear plastic box packaging

The process you choose for printing color on your packaging will influence the quality of the finished product, the consistency of your design from order to order, and your overall costs. That’s why 4 color process printing is ideal for producing packaging designs with impact branding. CMYK (Cyan, Magenta, Yellow, Key/Black) graphics can be printed in both translucent and opaque ink effects, leaving clear or translucent areas on your clear PET package to showcase your product. This is the best of both worlds where you can color brand your packaging and show what’s inside.

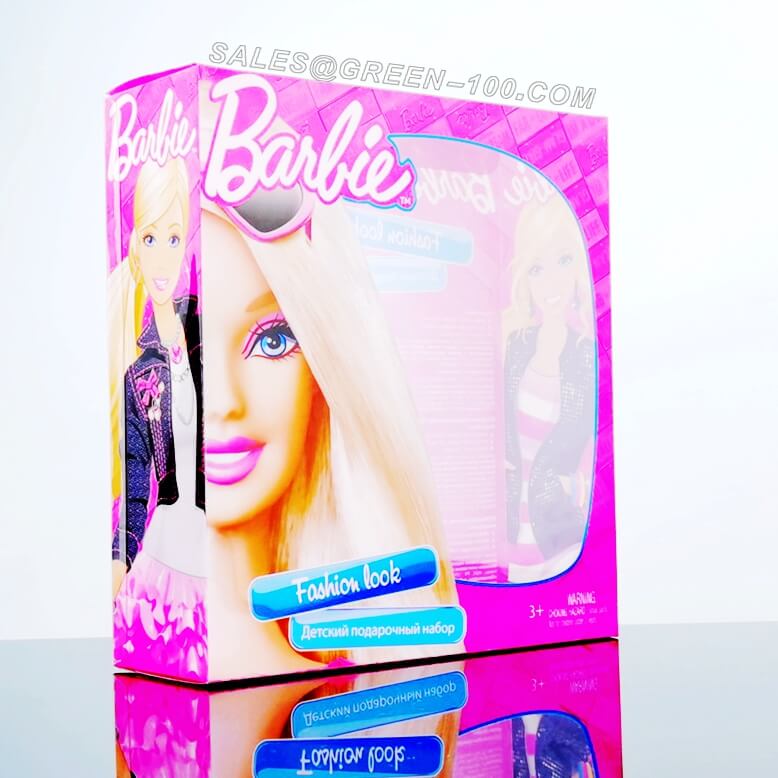

Cosmetic offset printing transparent and opaque window combination

When printing on a clear substrate such as PET for your folding box package or gravity feeder, you can print translucent colors or print white ink behind the colors to make the colors opaque and appear just as vibrant as if they were printed on a white substrate. With this in mind, our typical 4 color process is actually 4 colors plus white plus a UV protective coating. We can also add specialty spot colors (PMS) or an extra white to a 4 color process run. This process enables us to print translucent and opaque colors, to create graphics with metallic effects and realistic skin tones. We can also add details like texture, fragrance, embossing, hot or cold foil, and high-gloss or matte effects to create your ideal design.

Food-grade biscuit pet plastic box adopts CMYK+Pantone color combination

By using only four colors at different percentages-C (cyan), M (magenta), Y (yellow) and K (black)-you can create an unlimited number of colors, which makes CMYK printing a full-color photo Ideal for and other complex images containing more than three colors. In addition, you can add spot colors and varnishes for precise matching and effects. Other color printing processes use one color of ink to pave the ground, and this process uses tiny dots of CMYK ink to create images with unlimited color variations. Printing on transparent PET folding carton packaging allows you to showcase your products, build a strong brand image, and provide a design level that paper packaging cannot achieve. Create realistic skin tones, smooth gradients and metallic effects, and have incredible consistency between print jobs.

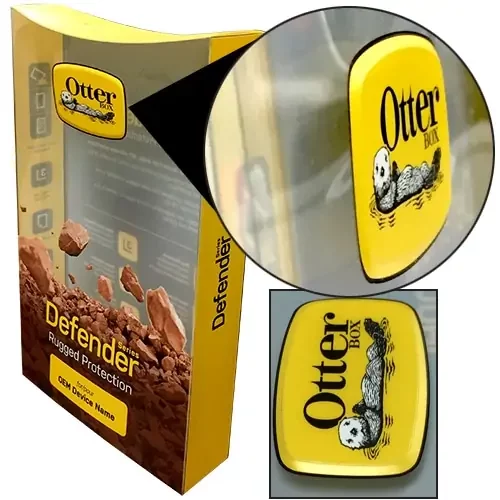

Advanced Craft of Plastic Box Packaging-Embossing

Simple embossed logo graphics and brand text

We can emboss your brand LOGO and text description wherever you need. It not only highlights the visual effect but also increases the difficulty and cost of reproducibility. The effect of embossing on the surface of the plastic box is much stronger than the 3D stereoscopic effect of the same process on the surface of the paper. And the touch is unsurpassed by other packaging materials.

Eco pet transparent plastic box + embossed LOGO

There is something unusual and impressive about embossing. It tells the customer that the product is outstanding and unique, and it’s worth taking another look. AGREEN PACKAGING can imprint your transparent plastic packaging perfectly, creating a true three-dimensional look and feel for your product image. When combined with offset printing or aluminum foil stamps, embossing can add a grade, value, and shelf appeal to your products.

High-frequency soft wire technology replaces ordinary die-cutting lines

Eco pet transparent plastic box + embossed LOGO

The company’s internal test data adopts plastic box packaging with soft lines + automatic bottom buckle, which is 5-6 times more efficient than normal-scale cutting and assembly.

The transparent packaging box with soft lines can not only improve the assembly efficiency but also strengthen the three-dimensional effect of the combined molding of the packaging box. With our unique anti-scratch plastic, it can avoid fingerprints, scratches, and dirt even during transportation or shelf display.

Custom Foil Printing and Stamping Services

Hot stamping

Bronzing involves more because it requires the creation of a mold or stamp. The stamp sets on top of the paper and heats and presses on the foil as it passes underneath. The pressure and heat give the aluminum foil a luxurious and eye-catching texture.

If you want to attract the attention of consumers and improve the brand’s firmness in the first time, the ecologically friendly PET and transparent PVC material packaging box with hot stamping process is a perfect combination.

Cold Foil Printing

For cold foil printing, an adhesive is first applied to the paper. The foil is then stamped and the adhesive is dried using UV light. The foil is then removed, leaving the parts above the adhesive. This process is an excellent choice for applying foil to a large area of the packaging. Usually we first process large-area hot stamping or laser hot stamping on plastic materials, and then print CMYK dot color combinations on the hot stamping, so that the entire printed pattern can be luxurious and sparkling.

Hot stamping, hot silver, and laser silver are the designs that consumers like. We have long used this process in gifts, food, health products, cosmetics and beauty tools, etc.

Plastic material anti-scratch, dirty and wear-resistant process

Under normal circumstances, transparent materials are easy to have fingerprints and scratches. The unique scratch-resistant material and technology of agreen packaging make you feel relieved to use plastic packaging materials without worrying about scratches and stains. Even if fingerprints and dirt are touched, they can be easily erased without leaving traces.