Custom Clear Pillow Boxes manufacturing company -PVC/PET/PP material

clear plastic pillow boxes

Transparent pillow boxes are available in fireproof PVC, ECO APET and recyclable materials.

The transparent surface can be used for screen printing, CMYK offset printing, embossing, hot stamping, hot stamping and silver stamping.

Frosted plastic pillow boxes packaging

The frosted material has excellent friction resistance. No scratches due to friction during transportation.

Appears translucent and hazy, usually made of PP material Eco-friendly and recyclable, the surface processing technology is the same as the transparent material.

pillow box packaging with holes

As you can see, the pillow case packaging can be customized with a hanging butterfly hole or a European hanging hole. Not only can you arrange your products neatly, but you can also sort and store them easily. And you also have enough advertising space to display the product’s features more prominently.

Our wiper blade pillow packaging box features a stylish pillow-shaped design that sets it apart from traditional packaging options. The curved edges and sleek appearance create a modern and eye-catching presentation, making it stand out on store shelves and grab customers’ attention.

Our manufacturing site

All materials, printing, molding and inspection are done at the same address

Manufacture of raw materials

Offset printing

Automatic Die Cutting Machine

Pillow boxes Gluing Line

QC, QA Workshop

What we do

Our Advantages

Professional Designer Team

Free design guidance to aid brand growth

Minimum Order Quantity

We can support customized production with a minimum of 3000 PCS

Leading Manufacturing Capabilities

Clean room with a daily production capacity of more than 500K.

Custom Clear Pillow Boxes-Manufacturer's Ultimate Guide

What are clear pillow boxes?

Clear pillow boxes are a type of packaging solution that combines the charming shape of a pillow with the transparency of clear plastic. These unique boxes are designed with a distinctive curved edge, resembling a pillow, and are made from high-quality transparent plastic material. The clear plastic allows for full visibility of the contents inside the box, making them ideal for showcasing and presenting various products in an elegant and captivating manner.

The use of transparent packaging box?

Clear pillow boxes are versatile and can be used for packaging a wide range of items, such as small gifts, jewelry, confectionery, cosmetics, and other retail products. Their crystal-clear visibility not only enhances the product presentation but also allows customers to quickly and easily identify the items without opening the packaging.

Table of Contents

Video about types and differences of clear pillow box

The above video describes in detail how to choose the material of the transparent plastic pillow case, the surface processing technology and some common customization problems You can also contact our professional sales specialists to consult the customization!

Many customers like to use transparent packaging boxes, which can display the products inside while protecting the products. If your product is very delicate and beautiful, this kind of clear pillow boxes tends to attract more customers’ attention.

The frosted plastic pillow boxes

The frosted pillow box looks translucent, you can see the outline of the product. This matte clear frosted pillow box can improve the texture of products and make your product look more premium.

Custom design printed pillow boxes

Why do so many people want to custom design pillow boxes? The eye-catching packaging design will make customers feel that you are working hard and your brand has great potential.

If you want customers to remember your products, you can choose to print your brand logo or product information on the pillow boxes, so that when customers have secondary needs in the future, they can purchase products or contact you through the company information on the custom pillow box, we accept custom pillow box printing,and we can provide free printable pillow box template.

Degradable transparent plastic pillow box packaging with hook

Material and thickness selection of plastic clear pillow boxes

We usually choose to use PVC, PET or PP material to produce pillow box

PVC is not an environmentally friendly material, but PVC is flame retardant and weather resistant. The surface hardness is high, compared to the abrasion resistance. The printing paper is high and can highly reproduce the printed color.

PET is an environmentally friendly material that is biodegradable and recyclable. PET is a biodegradable, recyclable and environmentally friendly material. In recent years, many customers pay more and more attention to environmental protection, so PET material is becoming more and more popular. In addition, PET material has very high transparency, so it is suitable for making transparent pillow gift boxes.

PP material is also an environmentally friendly material, biodegradable and recyclable, the transparency of PP is slightly lower than PVC and PET. But the flexibility is better, mostly used for cosmetic boxes. It is also commonly used to make frosted surface. Frosted pillow boxes are often made of PP material. If you want a translucent frosted effect, you can choose PP material.

Recommended thickness of PVC and PET material is 12# (0.30MM) PP material is usually recommended 16# (0.4MM).

What process options are available for customization

- Size (any size can be made according to need)

2. Surface printing (brand logo and description can be printed)

3. Embossing (brand logo and local special effects can be embossed)

4. Metallic effect (can be hot stamped gold and silver and any metallic color can be added)

5. Soft creasing (optional soft creasing process for 7x assembly speed)

6.Anti-scratch surface (Anti-scratch surface option can be added, no fear of transportation and shelf display friction)

Paper pillow boxes VS clear pillow boxes

Although many plastic materials have been recycled and degradable. However, if you pursue better compostable materials. At this time, I suggest you choose paper pillow boxes.

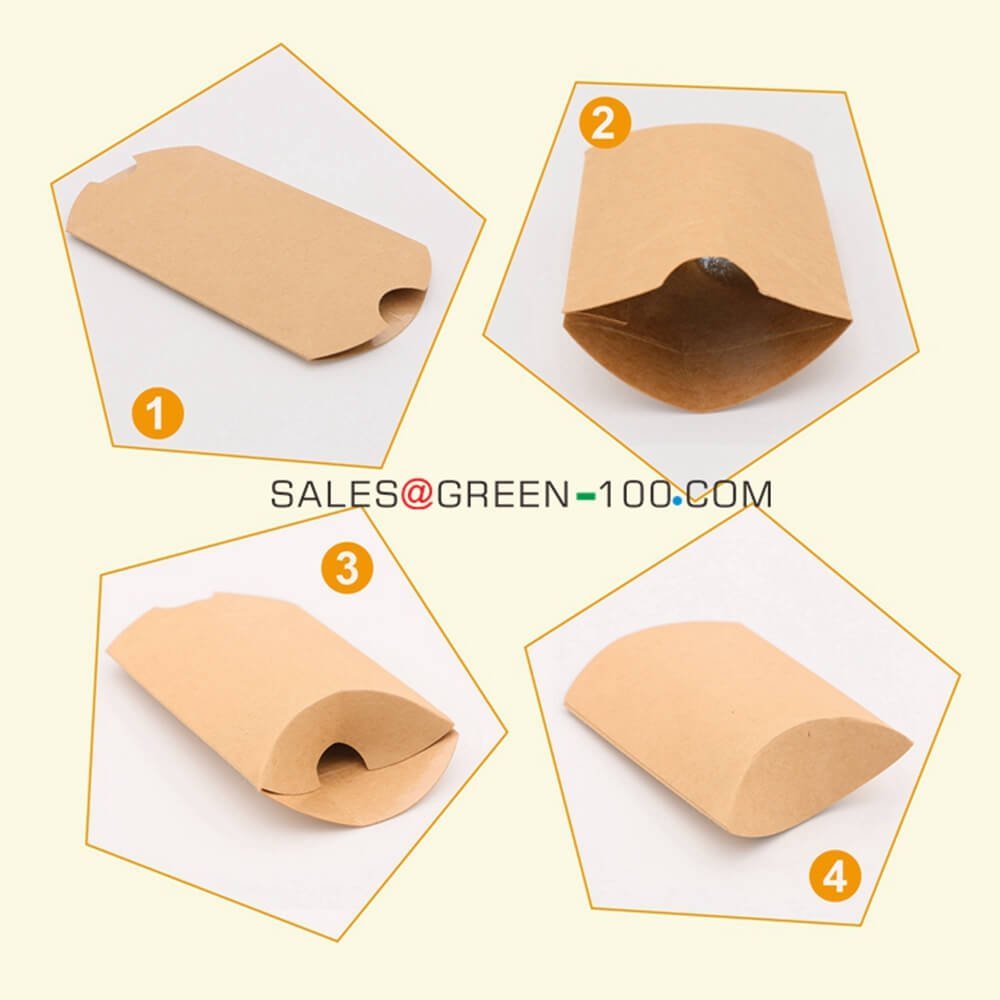

Kraft paper pillow box

In addition to clear plastic pillow boxes, we can also provide paper pillow boxes. The paper pillow box can be made of kraft paper or cardboard, which is more suitable for packaging some simple products, which will match very well. Paper is an environmentally friendly material, so many customers choose to order custom kraft pillow boxes. However, paper is not waterproof, and its anti-compression effect is not as strong as plastic. If your product is relatively fragile, we recommended choosing plastic pillow boxes with environmentally friendly PET materials.

Paper is better than plastic for manual operation, there are many pillow box templates available online. Many people can make pillow boxes by themselves based on templates

Pillow boxes with clear window

gold pillow boxes and silver pillow boxes

If you want your packaging to stand out on shelves and many products, the gold and silver pillow box is definitely a creative idea. It can be completely covered with gold and silver, or it can print colors on laser gold foil, which is more dazzling.

The structure of the pillow packaging boxes

The structure of the pillow packaging box is relatively singleness, you can choose whether you need to increase the hanger hole/ hook structure. If you need to put the goods on the shelf for sale, we recommend that you add a hanger hole on the top or the side of the box. If your pillow box is large, you can custom with a handle.

Because the surface of the pillow box has a curvature and is not flat, it can’t be placed upright like other boxes. But you can use the hanger hole at the top to hang it on the shelf to save more space. If you want to use a pillow box to wrap a gift, you don’t need to add a hanger hole. You can tie the pillow box with a ribbon to make a perfect gift box. If your product is clothes, what you need is to customize large pillow boxes with handles, which can be convenient for customers to carry.

MOQ, delivery and spare parts

For customized products, our MOQ is 3000pcs. If the quantity is too low, it will not only waste raw materials, but also damage the machine, and the unit price of the box will also be higher, which is not cost-effective.

Our delivery time is generally 12-15 working days after confirming the design drawing. If the order quantity is too large, it needs to be specifically negotiated.

We will provide 1% of the products as spare parts for each order, that is, if we order 3000 products, we will provide 30 spare parts.

We are also experts in international cargo transportation.

In the past 10 years, we have delivered goods to every customer quickly and safely.

We are not only proficient in international express delivery, shipping and railway transportation are also commonly used economic transportation methods.

Cooperating with us, you do not have to worry about transportation. Through a large amount of accumulation and communication, we have an absolute advantage in transportation costs, which can further save costs for you.

F.A.Q.

Problems worthy of attention in customizing transparent plastic boxes

- There are two main reasons:

The design of the size ratio is wrong, because both ends of the plastic pillow box are curved, and the ratio of the curvature needs to be adjusted according to the needs of different sizes to ensure easy folding. The wrong proportion design is the main reason for the difficulty of folding, and even the uneven force will cause the corners to crack. - The depth of the fold line indentation is not uniform, because the density of the plastic material is relatively large, and the production time requires a relatively large design accuracy and experience. If during the cutting process, the pressing depths of different areas in the same crease are different, the force will be uneven during the folding time, and the two sides will not fit tightly and be twisted.

- Talk to our sales Engineer

The direct reason why the plastic material is not transparent enough is that the raw materials used are inferior products, and the light transmittance of the material itself is relatively low. Another situation is that, in order to reduce costs, some manufacturers use informal recycling plastic processing procedures, causing foreign matter to be mixed in and reducing transparency.

The problem of scratches on the surface of transparent plastic materials is fatal. The reason why we like to use transparent pillow box packaging is that consumers can intuitively feel the goods inside. Scratches and scratches will not only reduce the transparency of the material but will also greatly affect the sensory of the entire packaging, which will have a negative impact on sales.

Avoid scratches and white spots. Production plants must protect surface cleanliness and material surfaces. The first step is to add a protective film or scratch-resistant coating on the transparent material.

If the surface of the packaging box provided by your supplier has no protective film or anti-scratch coating on you, then under normal circumstances, the cleanness and scratches of the plastic box cannot be guaranteed.

Yes, there is no problem. We can not only customize the size, print, and emboss on the surface. At the same time, it is also an international transportation expert, you only need to sit at home and wait for the goods.

Cracking of pillow cases is caused by improper selection of materials or poor quality of materials. In addition, if the material is too hard, it can’t be used to make a pillow box because the lid of a pillow box has a downward curve. If the lid is too hard, it will be difficult to close the box.

The assembly of a regular pillow case package is very simple, just put the pillow case on and close the lid and you’re done. The most important thing here is to close the lid with a semi-circular slit first. When you want to open the inner lid next time, you can easily use the gap to open the lid.

If the pillow case is difficult to assemble, it is most likely the result of improper or poor quality materials. Also, if the structure of the pillow case is not well made, it can be difficult to assemble because it is not coordinated.

When the material of the pillow case is thicker, assembly can be even more difficult. There is a solution though, and that is to add a soft crease when making the pillow box. It will make the box easier to fold. Regardless of the type of plastic box, adding a soft crease process can save a lot of assembly time.

Generally, the box bonding is completed by an automatic gluing machine, so the glue overflow problem rarely occurs. If you have unfortunately purchased a batch of boxes with overflowing glue, you will find that using tap water will not clean the glue on the boxes. Glue can’t be removed by cleaning and erasing, once the pillow box has overflowed glue, it can only be scrapped. So you need to choose a supplier with better quality control.